GPS SPEEDOMETER

I have long wanted to datalog

the amount of lift I get at the rear of my lakester. I did

fabricate a switched LED gizmo on the front axle to see if

there was any significant lift up there but, later, I

realized that the spring rate up front is over 1800 lb/inch

and there won't be any movement between the axle and frame

at this end of the car. Which isn't saying there isn't

lift, just that I can't measure it.

I've pondered many schemes for monitoring lift in the rear,

even bought some parts to connect a spring-loaded

potentiometer with a cable running over a drum down to the

axle housing. Complicated, and requires tools not in my

shop. Or even an indicator like Dan Hostetter installed in

his streamliner. He used a morse cable mounted on the frame

with one end fastened to the axle and the other sticking up

in the air in the cockpit in front of him. He put a small

piece of foam on the rod and pushed it down flush with the

cable housing end. As the car lifted, the cable would pull

in, sliding the foam up the rod. At the end of his run,

with the car back in equilibrium, the distance of the foam

piece from the cable housing end was the maximum lift the

car had experienced. Simple, yet quite effective. And,

since his purpose in building and modifying this car was to

experiment with aerodynamics and, in particular, handling

at speed, quite necessary information.

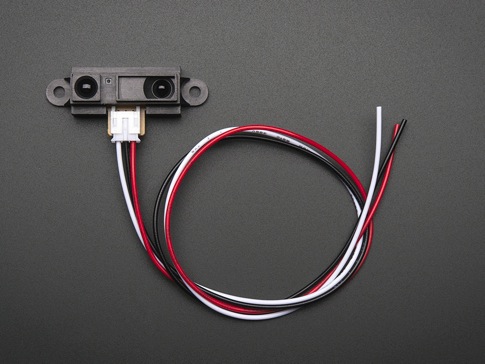

Ran across an infrared distance sensor on-line.

This handy gadget measures distance to a reflective

object in a strange, yet effective way: The LED on the

left emits light. The thing on the right that looks like

an LED is actually a lens; the light reflected from an

object is focussed on a CCD strip behind the lens. The

pixel with the strongest signal is proportional to the

angle of the reflected light. As you undoubtedly recall

from HS geometry, if you know the subtended angle and

the length of the base, you can calculate the distance

from the base to the point of the triangle -- the

distance of the object.

The output is a voltage -- handy for datalogging -- but it

is not linear, of course. It involves trignometry and some

constants that I don't know. However, the datasheet has a

graph of output voltage versus distance (actually versus

inverse distance), but I think I'll just make some

measurements of my own and, over the small changes in

distance I expect (hope) in this application, I can

probably come up with a linear scale factor to turn volts

into lift in inches.

This guy runs on 5V, which happens to be available from my

datalogger. Outputs a voltage in the span 0-5V. Should be

very simple to mount, all I have to do is paint a white

patch on the differential housing for it to reflect from.

Oh, yes. It costs $15!