TAPS-6 OUTPUT TRANSFORMERS

This transformer design was developed for the BITS/TAPS

instrument series in 1994-5. The goal was an output

transformer that could provide about 100 W electrical drive

to a 50 Ω

resistive load from our basic switching power amplifier

running on +15V DC.

It was found that two designs were necessary, one for

frequencies up to 700 kHz and another for frequencies above

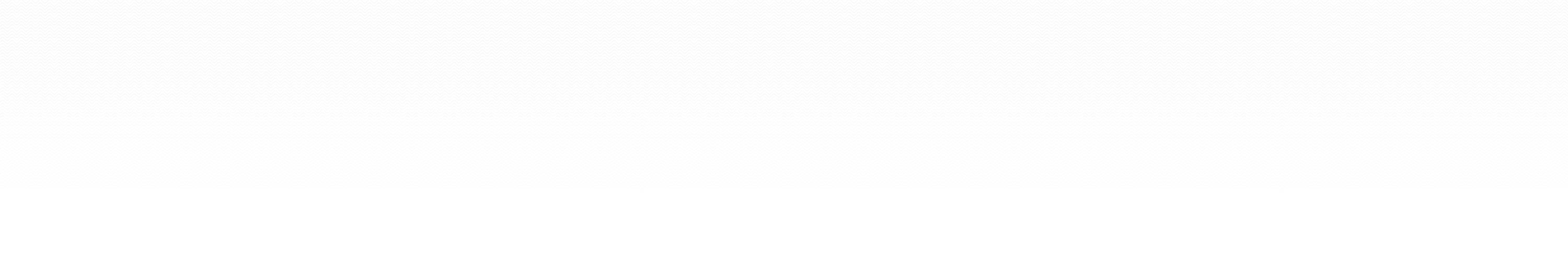

700 kHz. In all cases, the physical configuration is a 2616

case with PCB mount (2616F1D bobbin in a 2616HD hardware

kit). Primary wires are 20 AWB magnet wire, secondaries are

22 AWG. The basic 'kit' of parts is shown below:

LOW

FREQUENCY

The core is a 2616 PL00-3E2A ungapped potcore pair.

A bundle of wires is prepared: 2 primary wires and 8

secondary wires. One end of the group is captured in a vise

and the bundle is twisted together fairly tightly using a

pair of pliers. This bundle is then wrapped tightly around

the bobbin 4-1/2 times and wrapped with Kapton tape.

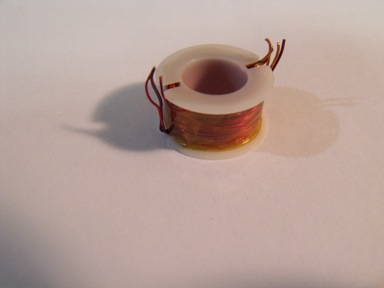

The bobbin and wire bundle is assembled into the potcore

and slipped into the metal can on top of a spring. A

terminal plate is aligned with the tabs on the can and the

tabs forced down to secure the potcore and plate into the

can (fig.below).

One primary wire from the right-hand (RH) bundle is

soldered to pin 4. The other end of this wire (in the LH

bundle) is found with an ohm-meter and brought across to

pin 3. The other primary wire from the RH bundle is also

soldered to pin 3. The other end of this wire from the LH

bundle is soldered to pin 5. This completes the primary

wiring. One secondary wire from the LH bundle is soldered

to pin 8. The other end (from the RH bundle) is found with

the ohm-meter. This wire is spliced to any wire from the LH

bundle and the splice covered with shrink-tubing. The other

end of this wire (from the RH bundle) is found with the

ohm-meter and it is also spliced to a wire from the LH

bundle. This process continues until only one wire is left

from the RH bundle; this wire is soldered to pin 1.

HIGH

FREQUENCY

This transformer is similar in construction to the

low-frequency transformer, except that the core material is

2616-PL00-3F3. Also, the secondary winding is formed from 5

wires (and the wire bundle is wrapped around the bobbin

3-1/2 times.

DESIGN

The purpose of the output transformer is to efficiently

couple energy from the switching transistors connected to

the +15V power supply to the output load. If we want to

develop, say, 100 W of transmitter power, we will need to

push about 6.7 amps through the switching transistors. On

the load side (we assume 50 ohms here), we need to develop

about 70.7V across the (resistive) load. Thus, we need to

step up the 15V available at the transistors to about 71V

at the load, a step-up ratio of about 4.7:1.

I have used DC voltages in the approximation above. This is

legitimate in this case because the switching amplifier

waveforms are essentially square-waves. The power

dissipated in a resistive load by a square wave is the

square of the peak voltage divided by the resistance (P =

V^2 / R).

Also, I have used the ratio of the output winding to one

primary winding as the step-up ratio. This is a

simplification of a slightly more complicated situation. If

you examine the voltages at the ends of the primary

windings, you will find that it fluctuates between nearly

0V and TWICE the supply voltage. When one transistor is

turned on and current flows in that half of the primary

winding, it induces a voltage in the other winding that

ADDS to the center-tap voltage to produce 2 E volts.

Similarly, when this transistor shuts off and the other

transistor turns on, the voltage on the primary will

reverse and 2 E volts will appear on the opposite winding.

So the turns ratio of the transformer is Vout / 2*Vin if

the whole primary winding is considered. Or, the turns

ratio is Vout / Vin if just one-half of the primary winding

is considered.

I developed an Excel spreadsheet to help me design

transformers. This spreadsheet (see the DOWNLOADS page)

lets you enter the parameters of a particular potcore size

and material and then design a transformer to produce the

power you want from the DC voltage you have available for

your power amplifier. It is specific to a push-pull,

digital amplifier like the ones shown in the SCHEMATICS

sections of the TAPS descriptions. The spreadsheet assumes

that the transistors will have some on-resistance that

prevents the primary end-point voltages from coming quite

to 0V, leading to more realistic estimates of output power.

The spreadsheet also calculates the core flux density for

the given power and frequency for comparison with the

maximum values specified by the manufacturer.