TAPS

This acronym used to stand for Tracor Acoustic Profiling

System. That was when Tracor, Inc. was a publicly held

corporation, headquartered in Austin, TX. Our office in San

Diego conducted acoustical research, principally for the

Navy, including some basic research on the use of

multi-frequency acoustics to measure and quantify

zooplankton distributions in the ocean. As a part of that

research, I designed a series of acoustic sensors that

eventually became TAPS. Previous systems evolved from

collections of individual transducers on a frame and

culminated in a 21-frequency system built (by Van Holliday

and Dave Doan) on a surplus mine-hunting sonar towed body.

This system drew power from shipboard equipment. The TAPS

sensors were a compromise design intended to provide useful

data in a portable package running on internal batteries.

Tracor was taken private in the late '80s, went through

bankruptcy, and emerged as a public company once again --

only to be purchased by General Electric PLC (of England).

Tracor was included in the Marconi Electronics group which,

a few years later, was merged with God-knows-what-all from

British Aerospace to become BAE SYSTEMS. And we were firmly

advised that the BAE portion had absolutely no connection

to British Aerospace and was just a name. I suppose that

BAE SYSTEMS is still around -- I get my retirement check

every month.

The TAPS-6 concept derived from the early MAPS systems but

the design began with some 2-frequency systems used on the

BITS mooring that I designed and a 4-frequency predecessor

that is now in mothballs. It was an interesting challenge:

to make a portable, internally-recording gadget that would

act like a ctd but could resolve zooplankton

size-distributions versus depth. It took a number of

iterations to get it pretty close to right.

The first problem was -- what frequencies should we use?

This was answered by selecting the target zooplankters:

copepods. These animals are reasonably-well-modelled by a

truncated fluid sphere model. Van Holliday spent several

hours on his computer to select four (later six)

frequencies from the 21 MAPS frequencies that seemed to

work well estimating size-abundance for these zooplankters.

Long after the fact, I spent some time trying to

rationalize the selection of frequencies and came up with a

way to select the span of frequencies needed for particular

copepod sizes. Fortunately, these approaches agreed with

each other pretty well.

The second problem involved the sample volumes for this

system. The sample volume can be computed from the pulse

length, the range, the speed of sound in water, and the

beam angle of the transducer used to transmit and receive

echoes. We discussed this at length; on the one hand, too

small a sample volume would mean sometimes there would be

very few scatterers in the sample volume -- making the

assumption of volume scattering incorrect. Too large a

sample volume would make it more likely that the relatively

rare larger scatterers (euphausiids, ctenophores, larval

fish, etc.) might contribute to the echo energy. We settled

on a sample volume of about a liter using transducers with

8-12° beamwidths and a 336 microsecond transmit pulse,

sampling at about 1m range. Note that this vastly

simplifies the assumptions we have to make, compared, say,

to an echosounder configuration where the sample volumes

increase inexorably with range.

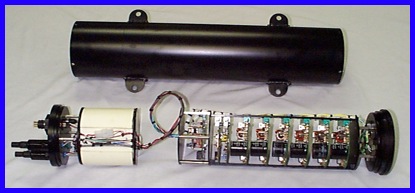

The picture above shows the original version of TAPS-6

exploded. The endcap on the right-hand side contains six

acoustic transducers, resonant at 265, 420, 700, 1100,

1850, and 3000 kHz. There are six transceiver cards (with

the large black capacitors) to drive these transducers. The

other endcap contains a depth sensor, temperature sensor,

and jacks to connect external sensors such as fluorometers

or conductivity sensors. A single-board-computer and

interface circuitry control the functions. A 21.6V NiCad

battery supplies power for 10-14 hours of operation.

The last TAPS (TAPS-6 NewGen) was a complete re-design

utilizing some concepts and designs from a series of

8-frequency systems that were built to operate on moorings.

These TAPS-8 units have been used extensively in the Arctic

by Jeff Napp at NOAA in Seattle. They are getting quite

long in the tooth and probably are nearly ready to be

replaced. The NG TAPS is used by Anne Lebourges-Dhaussy at

IFREMER in Brest, France.

BAE SYSTEMS no longer makes or supports TAPS -- I made a

deal with them when I retired to provide service for

existing customers in exchange for the spare parts and some

test equipment. If you need service or help with a TAPS,

contact me using the email link below. There is little to

no chance you could get me to build you one, but I could

certainly provide you with drawings, schematics, code, and

advice if YOU want to build one. All this information is in

the public domain. Eventually, all that information will

even be right here on this website. For as long as I am

around, anyway …