TRANSDUCER

DESIGN

This is where I plan to put the data I have accumulated on

transducer construction. I recently wrote a preliminary

report on building TAPS transducers. The first draft of

this report is on the downloads page. It contains the

information below plus some hints on testing, tuning, and

calibrating TAPS transducers. Feedback would be

appreciated.

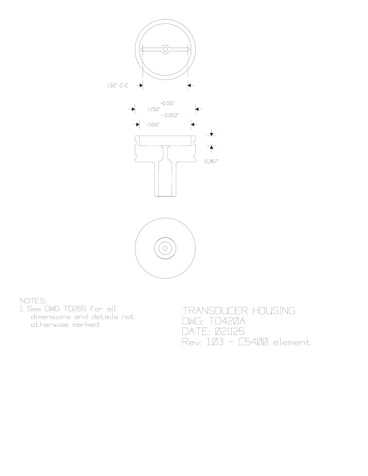

Ok, I did put a document on the DOWNLOADS page that

discusses the optimum thickness of backing materials on the

TAPS transducers. This won't make much sense without some

notion of how the transducers are made. Briefly, the TAPS

transducers are made from circular disk elements with

electrodes on the large faces. They are assembled into

housings like the drawing below. A thin piece of Copaco --

a tradename for a paper insulator used in electrical motors

-- is glued to the back side of the element using

Scotchcast 1838 structural adhesive and this assembly is

then glued into the housing. The cavity is then filled with

epoxy to waterproof the assembly and to provide a matching

layer from the ceramic to water.

I begin by soldering a wire to the back electrode at the

center. I prefer to attach the wire standing straight up

from the electrode; the wire is tinned and then soldered to

the electrode. This joint is tested for strength (gently),

then cleaned with MEK and a small dab of 5-minute epoxy is

applied to give the joint some mechanical strength.

When cured, the back is spread with a thin layer of

adhesive, the copaco backing (with a hole in the center) is

threaded over the wire, and another layer of adhesive

applied to the other side of the copaco.

A second wire is threaded through the hole in the housing

and along one of the machined channels in the transducer

cavity, lapping over the side of the housing. Structural

adhesive is applied to fill these channels and then the

transducer assembly (element and copaco) is inserted with

the attached wire fed through the hole with the other wire.

The element is rotated and pressed downward to create a

uniform thin layer of adhesive under the copaco. Extra

adhesive that is extruded can be removed with a Q-tip.

I cure these assemblies overnight with a small weight

pressing on the ceramic to ensure a thin joint. Use some

sort of non-abrasive material between the ceramic and the

weight to prevent damaging the upper electrode.

Next day, I inspect the transducer and then attach the

second wire to the face electrode. I usually tin the wire

and then flatten it with needlenose pliers before I solder

it to the ceramic. Then I hook up the wires to an

oscilloscope and thump the ceramic with the eraser end of a

pencil. You should see 100-200 mV peaks on the response.

The cavity is then filled with epoxy resin and left to cure

(again, overnight).

Day three has me attaching wires -- often RG-74 coax -- to

the two wires coming out the back of the housing. I try to

make a tidy joint that I can push into the housing and then

seal with more epoxy resin.